Share this page

Alignment with SDGs

AUTHOR

Hugo Scudino1, Jonas Toledo Guimarães1, Débora Lemos Lino2, Pedro Henrique Campelo3, Erick Almeida Esmerino1, Mônica Queiroz Freitas1, Tatiana Colombo Pimentel4, Marcia Cristina Silva2, Adriano Gomes da Cruz2* • Brazil

1Federal University Fluminense (UFF), Faculty of Veterinary, Amazonas, 69077-000, Brazil – 2Federal Institute of Education, Science and Technology of Rio de Janeiro (IFRJ), Departament of Food, Rio de Janeiro, 20270-021, Brazil – 3Federal University of Amazonas (UFAM), School of Agrarian Science, Amazonas, 69077-000, Brazil – 4Federal Institute of Paraná (IFPR), Paranavaí, Paraná, 87703-536, Brazil

Abstract

Dairy products are typically submitted to conventional thermal treatments (pasteurization and sterilization) to guarantee the food safety and shelf life. Other non-thermal treatments have potential to reduce energy and water consumption as well. These technologies can also preserve the quality parameters of the more sensitive products, such as non-enzymatic browning, protein denaturation, altered volatile flavour compounds, vitamin losses, and sensory acceptance.

Nonthermal technologies can be attractive to conventional dairy food processing by directly reducing energy and water consumption during processing and the energy impact during storage. Furthermore, they maintain the functional, nutritional, and sensory characteristics of the products. This article aims to overview nonthermal processing technologies, their principles, and examples of adoption by the dairy industry.

Introduction

Dairy products are positively accepted as their consumption provides health benefits to consumers (1) due to the presence of different nutrients.

Typically, they are subjected to treatments using high temperatures, such as pasteurisation and sterilisation. These technologies ensure food safety, but certain products may be reduced in sensory and functional properties (2). The dairy industry wants to improve its processing techniques to make them more sustainable due to high costs, energy and water consumption (3). The food industry is committed to making healthier and more sustainable products following the Food and Agriculture (FAO) strategy (4). The search for novel technologies that can maintain or increase the concentration of bioactive compounds in processed products is one of the challenges facing the dairy sector.

Nonthermal Processing: a new way to inactivate enzymes and microorganisms in dairy products

Non thermal processingmay have less impact on the sensory characteristics of the products than some heat treatments (2,5,6, 9, 10). It can meet microbial food safety standards and improve products’ physical, nutritional, and sensory characteristics, preserving unstable bioactive compounds and modulating enzymatic activity (3,7,8,9). (9).The idea is to develop applications of novel nonthermal technologies, eventually in combination with advanced thermal technologies, and ensure food safety by satisfying the requirement of a minimum 5-log reduction of the endogenous flora (11).

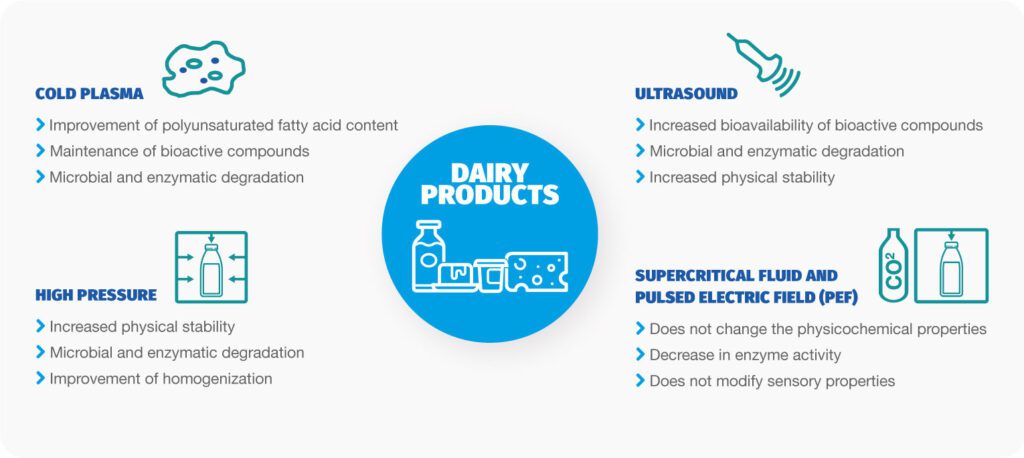

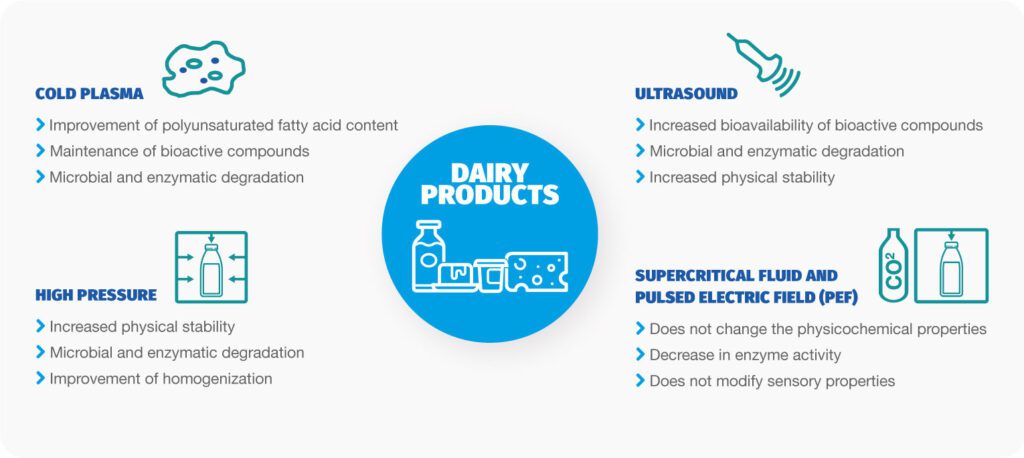

Figure 1 shows the main nonthermal technologies and their benefits on dairy products quality parameters commonly studied in recent years: high pressure processing, high-intensity ultrasound, cold plasma, supercritical carbon dioxide, and pulsed electric fields.

Non-thermal technologies can reduce energy and water consumption during processing and maintain the functional, nutritional and nutritional and sensory characteristics of products.

Hugo Scudino Tweet

Cold plasma, technology that maintains the concentrations of bioactive compounds of the dairy products

Cold plasma is an emerging technology that has been extensively studied in the food field, consisting of a cloud of highly energetic reactive species (12) capable of interacting with various food macromolecules, promoting cleavage or modification of these compounds (13–15). In addition to having a good effect on enzyme and microbial inactivation (7,16), cold plasma maintains the concentrations of bioactive compounds of the dairy products (17,18). Depending on processing conditions, the lipid profile can be altered. More drastic processes cause an increase in polyunsaturated fatty acids, while milder conditions can result in higher atherogenic and thrombogenic indices (17,18). The use of cold plasma in dairy products processing requires low temperature (about 25°C), which it has as consequence a direct reduction of energy and water consumption during processing, in addition it is characterized by the absence of water, solvents and residues.

High pressure technology can improve texture properties

High pressure processing is an important technology in the food sector and is widely used to process dairy products (19,20). Its mechanism of action is related to the conformational change of macromolecules, altering their chemical and biological activity due to the high pressure. These alterations can cause enzymatic inactivation and damage to the cell walls of microorganisms (20,21). In addition to increasing the shelf life of products, high pressure processing can impact dairy products’ other characteristics, such reduce the fat globules size (22), and improve texture properties (23). Regards the sustentability aspects, HPP requires lower temperature values with direct effect on the energy consumption which it is much lower than thermal process requiring cooling afterwards. However,it is important to mention that the high investment cost has been overcame by increasing the size of the equipment and the capacity of the vessel used.

Ultrasound technology for better microstructural changes while providing microbial and enzymatic inactivation

The mechanism of action of US is based on acoustic cavitation and acoustic transmission. In a liquid environment, such as milk, the passage of acoustic waves creates areas of compression and expansion, bubble collapse, and increased pressure and temperature at the implosion site. These mechanical impacts generate shear forces and contribute to mass transfer and particle displacement (3). Ultrasound treatment has stood out among nonthermal technologies due to several benefits related to microstructural changes and microbial (24) and enzymatic (25) inactivation in milk and dairy products. Also, ultrasound can increase the concentration of antioxidant compounds (26), reduce the size of fat globules (25) and increase physical stability (27,28). Depending on the treatment conditions, ultrasound can increase the concentration of saturated fatty acids (26) and reduce vitamins (26). One of the advantages of ultrasound are significant energy savings, as the temperature used in always lower than the traditional thermal processing. The use of ultrasound in dairy industry is likely to occur as a continuous flow system (CFS).

Supercritical carbon dioxide technology exerts no effect on the quality parameters

SCD combines pressure with carbon dioxide to inactivate microorganisms without affecting nutritional content and sensory attributes and is a promising alternative for processing dairy products (8). The main effects of carbon dioxide on enzymes and microorganisms are associated with changes in intracellular pH, causing metabolic disorders since the main biological pathways are very sensitive to changes in pH (8,29). However, the application of carbon dioxide in the processing of dairy products does not affect important properties such as pH, titratable acidity, soluble solids content, and bioactive compounds (30). It can also bring several benefits, such as reducing the size of fat globules (30). Furthermore, the use of carbon dioxide does not affect consumer sensory perception (30). At industrial level, SCD is a sustainable alternative to totally eliminate or greatly reduce the requirement of numerous conventional organic solvent, contributing for a lower generation of residues; furthermore, it operates using lower temperatures when compared to conventional thermal processing.

Pulse electric field improves the functional properties

PEF is another nonthermal technology with potential to inactivate microorganisms with preservation of heat-sensitive compounds of the food matrix (31). PEF technology is characterized by the treatment of food using two electrodes separated by an insulator. In this method, short pulses are generated by a high voltage pulse generator, which are responsible for functional and structural changes in the cellular membrane of microorganisms, causing their death (32).

PEF is considered as environment-friendly technology that can be applied in food processing for microorganism/enzyme inactivation and recovery of bioactive compounds as it has a high speed to achieve the operational parameters.. However, additional studies are need regards the in PEF equipment to decrease lower the energy costs to achieve results compared to standard pasteurization and transfer PET to the industrial level as more competitive technology

Conclusion

Nonthermal technologies can be attractive to conventional dairy food processing as they could reduce energy and water consumption during processing and maintain the functional and sensory characteristics of the products. However, the understanding of the application of nonthermal technologies needs improvement at the industrial level.

Most of them currently operate in-batch. Thus, developing devices for the in-flow operation would facilitate their transfer to the industrial manufacture of dairy foods. Therefore, investments and efforts in research are advisable to clarify some side aspects, such as environmental impact and reduction of food waste, that are receiving increasing attention and are not very well documented and need further studies related with each dairy food. Finally, studies covering consumer perceptions are lacking to show the right message to be added to the dairy food’s label, and hedonic and descriptive studies that would be interesting to evaluate the optimization of operational parameters.

References

Verruck S, Balthazar CF, Rocha RS, Silva R, Esmerino EA, Pimentel TC, et al. Dairy foods and positive impact on the consumer’s health. Advances in Food and Nutrition Research. 2019. 89: 95–164.

Ribeiro NG, Xavier-Santos D, Campelo PH, Guimarães JT, Pimentel TC, Duarte MCKH, et al. Dairy foods and novel thermal and non-thermal processing: A bibliometric analysis. Innov Food Sci Emerg Technol 2022; 76:102934.

Guimarães JT, Scudino H, Ramos GL, Oliveira GA, Margalho LP, Costa LE, et al. Current applications of high-intensity ultrasound with microbial inactivation or stimulation purposes in dairy products. Curr Opin Food Sci. 2021;42:140–7.

FAO. 2020 Global Nutrition Report. 2020. p. 1–5.

Alsaleem KA, Hammam ARA, Awasti N. Safety, Regulatory Aspects and Environmental Impacts of Using Nonthermal Processing Techniques for Dairy Industries. Non-Thermal Process Technol Dairy Ind. 2021;157–72.

Selvamuthukumaran M, Maqsood S. Non-Thermal Processing Technologies for the Dairy Industry [Internet]. Boca Raton: CRC Press; 2021. Available from: https://www.taylorfrancis.com/books/9781003138716

Coutinho NM, Silveira MR, Rocha RS, Moraes J, Ferreira MVS, Pimentel TC, et al. Cold plasma processing of milk and dairy products. Trends Food Sci Technol. 2018;74:56–68.

Amaral G V., Silva EK, Cavalcanti RN, Cappato LP, Guimaraes JT, Alvarenga VO, et al. Dairy processing using supercritical carbon dioxide technology: Theoretical fundamentals, quality and safety aspects. Trends Food Sci Technol. 2017;64:94–101.

Chacha JS, Zhang L, Ofoedu CE, Suleiman RA, Dotto JM, Roobab U, et al. Revisiting nonthermal food processing and preservation methods—action mechanisms, pros and cons: A technological update (2016–2021). Foods. 2021;10: 1430

Jadhav HB, Annapure US, Deshmukh RR. Nonthermal Technologies for Food Processing. Front Nutr. 2021;8::1–14.

Režek Jambrak A, Donsì F, Paniwnyk L, Djekic I. Impact of Novel Nonthermal Processing on Food Quality: Sustainability, Modelling, and Negative Aspects. J Food Qual. 2019;article ID 2171375, 2 pages, 2019.

Turner M. Physics of Cold Plasma. In: Cold Plasma in Food and Agriculture [Internet]. Elsevier; 2016. p. 17–51. Available from: https://linkinghub.elsevier.com/retrieve/pii/B9780128013656000020

de Castro DRGDRG, Mar JMJM, da Silva LSLS, da Silva KAKA, Sanches EAEA, de Araújo Bezerra J, et al. Dielectric barrier atmospheric cold plasma applied on camu-camu juice processing: Effect of the excitation frequency. Food Res Int 2020 May;131: 109044.

Loureiro A da C, Souza F das C do A, Sanches EA, Bezerra J de A, Lamarão CV, Rodrigues S, et al. Cold plasma technique as a pretreatment for drying fruits: Evaluation of the excitation frequency on drying process and bioactive compounds. Food Res Int. . 2021: 147:110462.

Carvalho APMG, Barros DR, da Silva LS, Sanches EA, da Costa Pinto C, de Souza SM, et al. Dielectric barrier atmospheric cold plasma applied to the modification of Ariá (Goeppertia allouia) starch: Effect of plasma generation voltage. Int J Biol Macromol 2021182:1618–27.

Coutinho NM, Silveira MR, Rocha RS, Freitas MQ, Duarte MCKH, Quero RF, et al. Cold Plasma. In: Sustainable Food Processing and Engineering Challenges Elsevier; 2021. p. 109–35.

Silveira MR, Coutinho NM, Esmerino EA, Moraes J, Fernandes LM, Pimentel TC, et al. Guava-flavored whey beverage processed by cold plasma technology: Bioactive compounds, fatty acid profile and volatile compounds. Food Chem. 2019;279:120–7.

-

Coutinho NM, Silveira MR, Fernandes LM, Moraes J, Pimentel TC, Freitas MQ, et al. Processing chocolate milk drink by low-pressure cold plasma technology. Food Chem.. 2019;278:276–83.

-

López-Fandiño R. High pressure-induced changes in milk proteins and possible applications in dairy technology. Int Dairy J. 2006;16:1119–31.

-

de Castro Leite BR, de Oliveira MM, Cristianini M. High-Pressure Technologies in Dairy Processing: Quality Maintenance and Increase in Consumption. In: Food Processing for Increased Quality and Consumption [Internet]. Elsevier; 2018. p. 149–77.

-

da Cruz AG, Fonseca Faria J de A, Isay Saad SM, André Bolini HM, SantAna AS, Cristianini M. High pressure processing and pulsed electric fields: Potential use in probiotic dairy foods processing. Trends Food Sci Technol. 2010;21:483–93.

-

Masbernat O, Risso F, Lalanne B, Bugeat S, Berton M. Prediction of size distribution in dairy cream homogenization. J Food Eng. 2022;324

-

Levy R, Okun Z, Shpigelman A. Utilizing high-pressure homogenization for the production of fermented plant-protein yogurt alternatives with low and high oil content using potato protein isolate as a model. Innov Food Sci Emerg Technol. 2022;75(December 2021).

-

Guimarães JT, Balthazar CF, Scudino H, Pimentel TC, Esmerino EA, Ashokkumar M, et al. High-intensity ultrasound: A novel technology for the development of probiotic and prebiotic dairy products. Ultrason Sonochem [Internet]. 2019;57(March):12–21. Available from: https://doi.org/10.1016/j.ultsonch.2019.05.004

-

Scudino H, Silva EK, Gomes A, Guimarães JT, Cunha RL, Sant’Ana AS, et al. Ultrasound stabilization of raw milk: Microbial and enzymatic inactivation, physicochemical properties and kinetic stability. Ultrason Sonochem [Internet]. 2020 Oct;67(September 2019):105185. Available from: https://linkinghub.elsevier.com/retrieve/pii/S1350417719314579

-

Guimarães JT, Silva EK, Ranadheera CS, Moraes J, Raices RSL, Silva MC, et al. Effect of high-intensity ultrasound on the nutritional profile and volatile compounds of a prebiotic soursop whey beverage. Ultrason Sonochem [Internet]. 2019;55(January):157–64. Available from: https://doi.org/10.1016/j.ultsonch.2019.02.02

-

Monteiro SHMC, Silva EK, Guimarães JT, Freitas MQ, Meireles MAA, Cruz AG. High-intensity ultrasound energy density: How different modes of application influence the quality parameters of a dairy beverage. Ultrason Sonochem 2020;63: 104928.

-

Scudino H, Guimarães JT, Cabral L, Centurion VB, Gomes A, Orsi AS, et al. Raw milk processing by high‐intensity ultrasound and conventional heat treatments: Microbial profile by amplicon sequencing and physical stability during storage. Int J Dairy Technol. 2022; 75:115–28.

-

Perrut M. Sterilization and virus inactivation by supercritical fluids (a review). J Supercrit Fluids. 2012;66:359–71.

-

Amaral G V., Silva EK, Costa ALR, Alvarenga VO, Cavalcanti RN, Esmerino EA, et al. Whey-grape juice drink processed by supercritical carbon dioxide technology: Physical properties and sensory acceptance. LWT – Food Sci Technol. 2018;92:80–6.

-

Gentès M C, Caron A, Champagne C P. Potential applications of pulsed electric field in cheesemaking. International Journal of Dairy Technology. 2022.

-

Sampedro F, Rodrigo D. Pulsed electric fields (PEF) processing of milk and dairy products. In: Emerging dairy processing technologies: Opportunities for the dairy industry. John Wiley & Sons. 2015; 115-148.