Share this page

Co-composting of residual fats from the dairy industry separated by a dissolved air flotation equipment (DAF)

Alignment with SDGs

AUTHOR

Carlos Martin1, Erica Schmidt2

1 Instituto de Desarrollo Tecnológico para la Industria Química (INTEC), Universidad Nacional del Litoral y CONICET, Santa Fe, Argentina; 2 INTI Lácteos, Rafaela, Santa Fe, Argentina.

Introduction

The dairy chain is one of the most important and dynamic agri-food complexes in the Argentine economy, for many years, this type of industry has experienced a remarkable growth, which involved a greater generation of liquid effluents and biosolids. The industrialization of the milk originates different products, because of that; the characteristics of the contamination vary considerably (Carvalho et al., 2013).

The most important environmental problem in the dairy industry is the generation of wastewater, both because of its volume and the associated pollutant load, mainly of organic nature. If these effluents are not treated properly, they cause problems of contamination in soils or natural water in which are discharged.

Dairy wastewater is characterized by high biological oxygen demand (BOD) and chemical oxygen demand (COD) concentrations, and generally it contains fats, nutrients, lactose, as well as detergents and sanitizing agents.

Due to dairy wastewater are highly biodegradable, it can be effectively treated by biological processes that combine anaerobic, aerobic and facultative reactions. Independently of the type of effluent treatment system carried out, the presence of FOGs (fat, oil, grease) in the effluents can cause different kinds of problems in the biological treatment systems, therefore it is essential to reduce or eliminate completely these components before to any treatment (Britz and Mostert, 1977).

Common techniques for treating dairy industry wastewaters include grease traps, oil water separators, equalization of flow, and clarifiers to remove solids. Over the last ten years, there has been an increasing interest on the use of Dissolved Air Flotation equipments (DAF) for clarifying solids from biological systems. DAF is a relatively simple technology that uses fine air bubbles to separate liquid particles and light suspended solids (mostly fats) from wastewater. These particles and solids are floated via the bubbles to the surface of a flotation cell for removal from a wastewater stream.

The management of these biosolids (DAFw) is complicated, this type of waste has similar properties that sludge from grease traps and was expected to be suitable for biological treatment in anaerobic reactors or aerobic composting using several co substrates as bulking agents and C-N sources (i.e., wood shavings and chips, green grass among others).

Most of the times, the proper disposal of these biosolids generates high costs, so it is essential to find options that are reliable, legally acceptable, economically viable and easy to implement. Thus, there is a need to search for biosolids transformation systems, optimizing their reuse through the exploitation of their components, allowing them to reintegrate into the soil and therefore to the biogeoecological cycles.

Many research groups have investigated the limitations of anaerobic fat treatment, focusing mainly on the inhibitory action of long-chain fatty acids on methanogenic bacteria (Davidsson et al. 2008). Meanwhile, several groups of researchers studied with favourable results the co-composting of residues of a lipid nature (Ruggieri et al. 2008), which leads us to suppose that this residue from the DAF would be efficiently treated in co-composting processes.

In this sense, the aerobic processes of degradation, such is the case of composting would be more effective for the treatment of residual fats. Composting involve the decomposition and biological stabilization of organic substrates. Composting is a microbiological process in which different microbial communities initially degrade organic matter into simpler nutrients and, in a second stage, complex organic macromolecules such as humic acids are formed (Hsu and Lo, 1999). It is an aerobic process, which requires oxygen to achieve optimal microbial biodegradation, moisture and porosity. It is a transformation process by which, under controlled operating conditions, the organic matter contained in the waste is biologically degraded in an aerobic form generating gases (CO2 and NH3) and a stabilized solid (compost) that it admits multiple uses and depending on its quality, it can be used as a soil fertilizer (Cayuela et al. 2009).

The main objective of this work was to study the viability of the composting of DAFw with different co substrates and determine the effect of different proportions of DAFw on composting efficiency and final compost quality.

Materials and methods

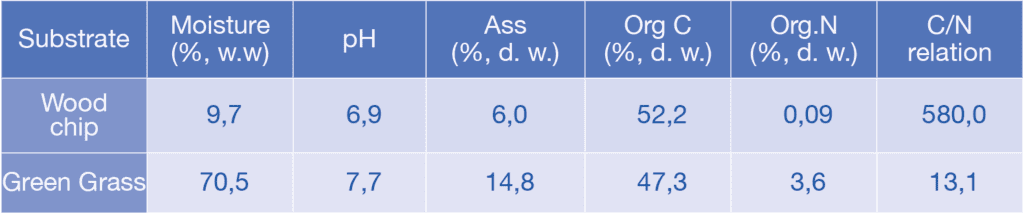

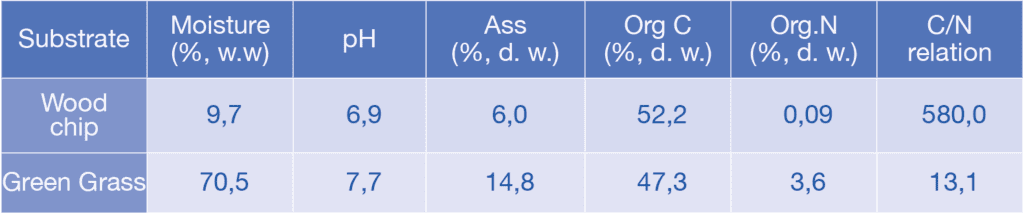

Different amount of DAFw (70, 60, 50, 30, 0 % w/w) from a local dairy industry were added to a mixture of wood chips and green grass as bulking agent and C/N source. The composting process was performed in open air windrows (100 L ca.) with periodical turnovers. The physical – chemical characterization of the residues were carried out following standardized protocols.

Based on the characterization carried out, the reactors were assembled, for which the appropriate combination of the RSO was formulated in order to obtain an initial substrate of the desired characteristics depending on the variable to be studied.

In order to evaluate the process many laboratory analyses were carried out, its included moisture, temperature, particle size, electrical conductivity, pH, Nitrogen (Kjeldahl), ash, organic matter and grease. Furthermore, phytotoxicity of the compost was studied using germination test (relative seed germination, RSG).

The dissolved air flotation waste is feasible to use in aerobic co-digestion processes improving the environmental management and sustainability in the dairy industry

Erica Schmidt Tweet

Preliminary Results

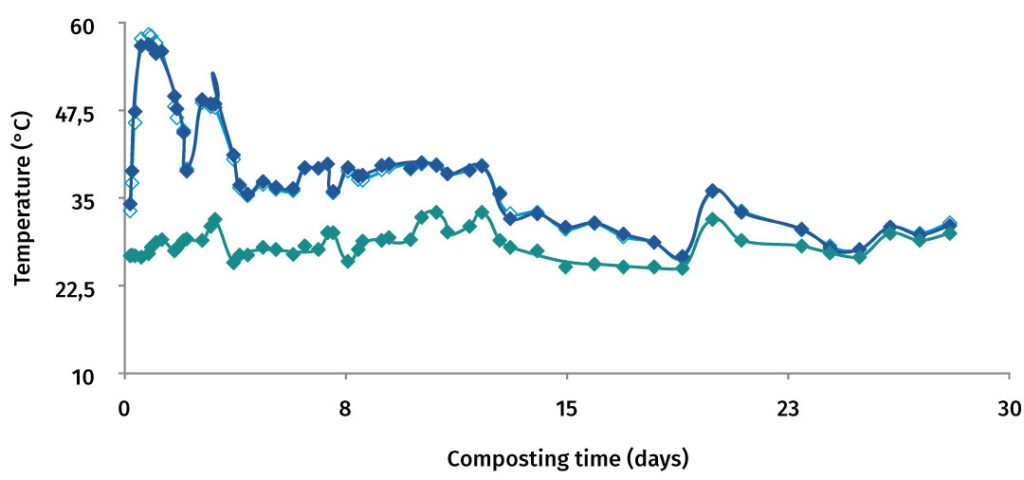

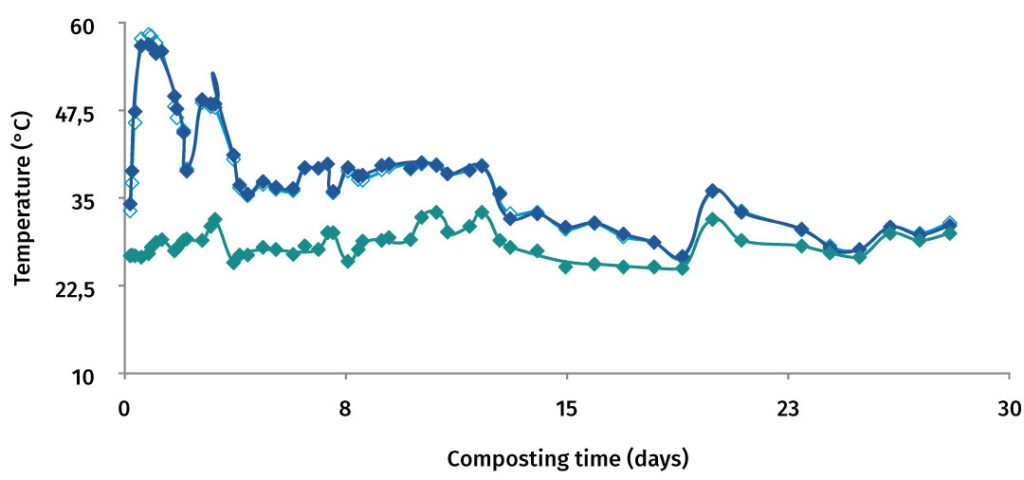

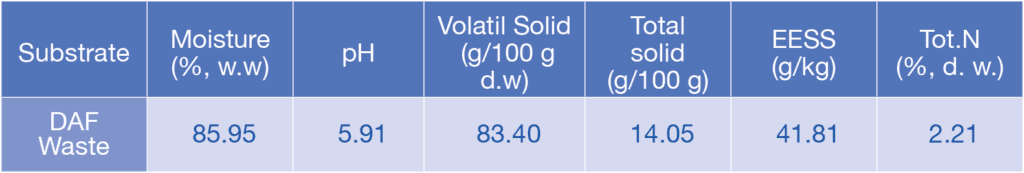

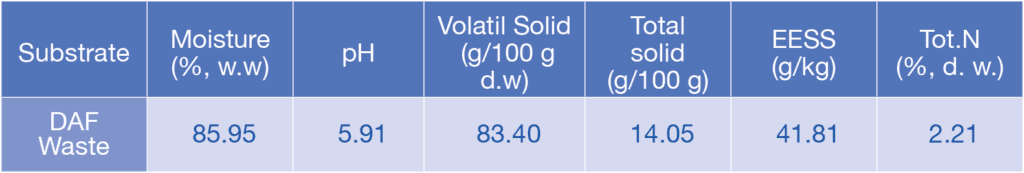

The evolution of the temperature has been carefully considered. When DAF waste was added to the mixture the temperature reached the thermophilic range in comparison with a blank mixture without DAFw (Figure 1). It is possible to conclude the feasibility of the DAFW valuation using composting process and the improvement of quality of the obtained final product. Tables 1 and 2 show the characteristic the results of the characterization of the waste used

Conclusion

From the analysis parameters of various set of experiences, the best results in terms of process efficiency has been obtained in reactors containing from 40 to 60% DAFw, these results allow us to affirm the hypothesis that this residual biosolid from the dairy industry can be valorised through composting processes in co-digestion with other organic waste.

Regardless of the conditions studied, 100% of the reactors to which DAFw have been added have shown better efficiencies in terms of thermal behaviour. These being significant within 24 to 72 hours of the beginning of the process.

According with these results, DAFw has been used as a co-substrate in mixture with other organic residues that present lower energy content, DAFw would help to reach the temperature ranges for sanitization of the compost since it is considered that the death of pathogens occurs with a temperature of 55 ° C for at least 72 hours.

The percentage of DAF waste used directly affects the quality of the final product. A final product with good physical and chemical quality has obtained, resulting in beneficial effects for plant physiology.

Based on the results obtained it was possible to observe that the dissolved air flotation waste is feasible to use in aerobic co-digestion processes improving the environmental management and sustainability in the dairy industry.

References

- Britz, T., Mostert, J. (1977). Two – phase anaerobic digestion of three different dairy effluents using a hybrid bioreactor. Water S.A, 23, 151 – 156.

- Carvalho F., Prazeres A & Rivas J. (2013). Cheese whey wastewater: Characterization and treatment. Sci.Total Environ. 445–446 385–396.

- Cayuela M.L.; Mondini C.; Insam H.; Sinicco T. y Franke-Whittle I. Plant and animal waste composting: effects of the N source on process performance. Bioresoruce Technol. 100 (2009) 3097-3106.

- Davidsson C., Lo¨vstedt J., la Cour Jansen C. (2008). Co-digestion of grease trap sludge and sewage sludge. WM&R 28 986–992.

- Hsu, J., Lo, S. Chemical and spectroscopic analysis of organic matter transformations during composting of pig manure. (1999). Environ Sci Pollut R104, 189–196.

- Ruggieri, L., Artola A., Gea T. (2008). Biodegradation of animal fats in a co-composting process with wastewater sludge. Biotechnol. Bioeng. 62 297–303.