Share this page

Alignment with SDGs

AUTHOR

Vishal Trivedi, Harendra Pratap Singh, Lalita Oraon, Ketan Dave, Aditya Jain, DK Sharma,

Product and Process Development, National Dairy Development Board, Anand, Gujarat, India.

Background

In last few years, people have become more health conscious which encourages them to daily exercise, meditation/yoga, eat healthy and nutritious food. Now-a-days people choose those foods which promote their welfare and reduce the risk of diseases. In addition to this, change in life style, increase in the number of working women, eating habits and time shortage calls for food which is healthier and also convenient to use.

Dahi-based spread incorporates benefits of fermentation and spread ability and is a combination of higher protein and/or lower fat than the conventional spreadable products. It is also convenient to use and can be eaten with a variety of foodstuffs.

The Process

During the product development phase several recipes and process parameters were tried. First step was to select culture which leads to minimum or no whey separation after fermentation. Generally, preparation of concentrated curd requires whey draining after fermentation. However, in case of this dahi spread, the process has been so standardized that whey draining is not required. After that the challenge was to increase the viscosity of the product to a desired level. Also, several ways to increase the shelf-life of the product were tried.

Finally, a multi-step process was standardized for commercial manu-facturing of the product which is as follows:

a. Milk Standardization

Milk is standardized to 8.5% fat and 18% SNF. Milk derived cream and skimmed milk powder were used for the purpose of standardization. The cream is added when temperature of milk reaches about 400C and skimmed milk powder is added when temperature reaches to around 550C for better reconstitution.

b. Pre-heating and addition of sugar and stabilizers

Standardized milk is then preheated to 60-650C and added with sugar along with the chosen stabilizers into the milk. The contents are mixed properly.

c. Filtration

The contents are properly filtered through stainless steel strainer.

d. Heating

The contents are heated at 850C for 10 minutes. However other suitable time–temperature combination can be used.

e. Cooling

The contents are cooled to a temperature at which inoculation of the culture can be done. This temperature should be favourable for the culture growth.

f. Inoculation

Inoculation is done with 1-2% MD culture (developed by National Dairy Development Board). The culture is specifically chosen as it can tolerate high osmotic process caused by high total solids content including sugar.

g. Incubation

Incubation is done till desired pH of about 4.6 is reached. The incubation temperature used should be suitable to the culture used. No whey draining is required after incubation.

h. Addition of condiments/flavouring substances and mixing

Addition of carrot shred, mint, tomato powder, salt, vinegar and potassium sorbate as anti-fungal agent (preservative-optional to increase shelf-life) is carried out. The contents are mixed properly and homogeneously with the help of planetary mixture. Other combinations of fruits, vegetables, spices, chocolate, fruit pulp, fruit preserves, etc. may be used.

i. Packing and storage

The product is packed hygienically in polypropylene cups and stored at refrigeration temperature (below 40C). Other suitable packaging material may be used.

Key outcome

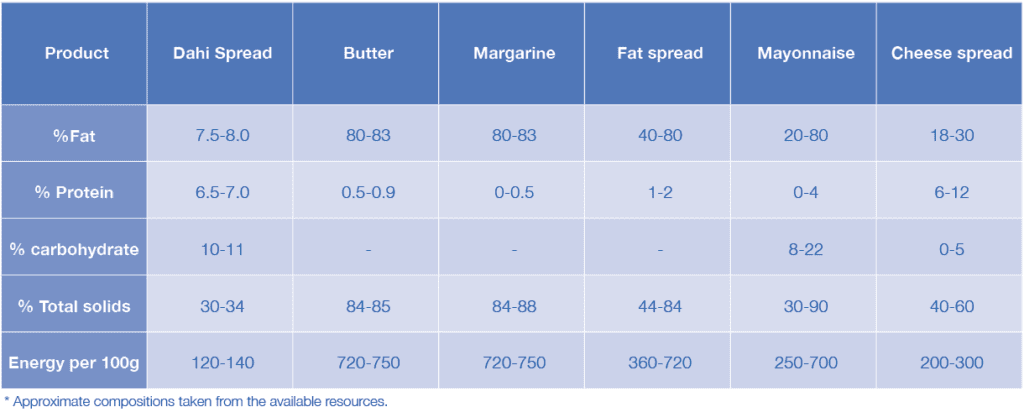

A product has been made using alteration in the dahi making process. The product has higher milk protein content than other commercially available spreads except cheese spread. Also, the product has lower fat content than most of commercially available spreads. The detailed comparison is given below in Table 1. It is a vegetarian product (as per the Indian food law) in which major portion of nutrients has been derived from milk source. Different variety of spreads can be made using different condiments, fruits and other flavouring substances. It can be used along with bread, parathas, chapatti, toast, crackers, etc. The results of sensory evaluation have indicated high acceptance of the product among the general population. The product has a shelf-life of 15 days when packed in polypropylene cups and stored at refrigeration temperature (4°C or below). However, its shelf-life can be increased to 2 months at refrigeration temperature by use of preservatives.

Relevance of the topic on the future of the dairy sector

Presently there are various types of spreadable products available in market, majority of which are either milk solids based or from vegetable fat origin. The products which come under this category are butter, margarine, fat spreads, mayonnaise, cheese spreads and other similar products.

Spreads are generally an integral part of meals, snacks & breakfast and this has led to their steady growth. Global food spread market is expected to register a CAGR of 3.5% during the forecast period, 2017 to 2022. (Mordor Intelligence, 2018). The global food spreads market is set to be of worth USD 15.6 billion by the end of 2015 (Business Wire, 2018). A rising health consciousness among consumers has paved the way for low calorie spreads having high protein content.

References

Business Wire (2018). Research and Markets: Global Food Spreads Market Worth USD 15.6 Billion by 2020 – Analysis, Technologies & Forecasts 2015-2020. https://www.businesswire.com/news/home/20151221005677/en/Research-Markets-Global-Food-Spreads-Market-Worth Last accessed 13 December 2018.

Mordor Intelligence (2018). Global Food Spread Market – Growth, Trends and Forecasts (2018 – 2023) https://www.mordorintelligence.com/industry-reports/global-food-spreads-market-industry Last accessed 13 December 2018.