Share this page

Alignment with SDGs

AUTHOR

Meenesh Shah, Chairman, Member Secretary, INC-IDF, NDDB • India

Abstract

Carrying forward the idea as presented in the article to actual implementation, NDDB chose two villages in Anand district of Gujarat State to examine the robustness of the Manure Value Chain model. A total of 450 Flexi biogas plants of 2 cubic meter capacity were provided to women beneficiaries in these two villages. The entire process from procurement, processing and sale was benchmarked and standard operating procedures established. On the governance side, in order to manage operations, NDDB helped establish India’s first women only manure cooperative. NDDB also extended its trademarked “SuDhan” brand to the cooperative for sale of manure products.

The responsible production as well as consumption of the organic manure promoted circular economy at the village level. During the two years of operations of the manure cooperative, 8.74 Lakh litres of slurry was procured from the farmers. The revenue of the manure cooperative grew by around 350% from INR 18.85 Lakh in 2020-21 to INR 64.34 Lakh in 2021-22. At the individual farmer level, the savings/ additional income accrued was INR 3500 per month. Overall value generation from the entire set of activities was to the tune of INR 237 Lakhs (USD 300,000).

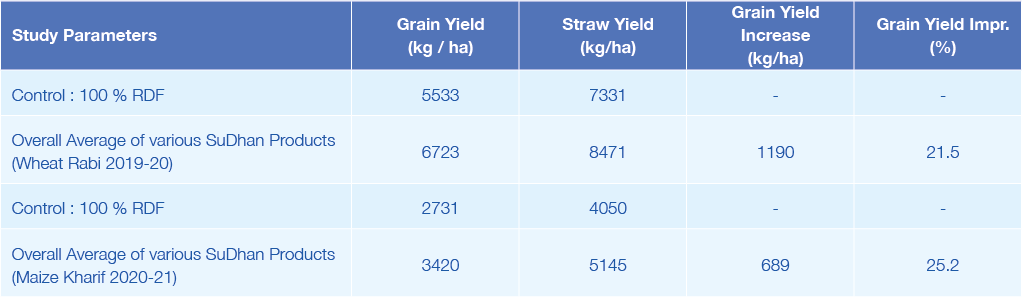

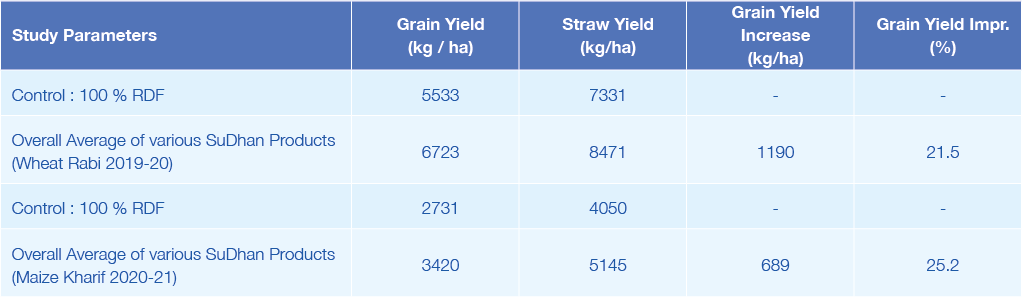

The usage of “SuDhan’ products increased grain yield of wheat and maize crop to the tune of 24 and 32 per cent respectively and reduced usage of chemical fertilizers by almost 25%.

Based on the learnings from the small-scale biogas projects, NDDB is also working on a unique model to meet the entire energy requirements of a dairy processing plant through biogas plant.

Reference is cited to National Dairy Development Board’s (NDDB) article published in IDF Dairy Sustainability Outlook 2020 which discussed about the initiative towards establishing a robust Manure Value Chain augmenting livelihood security of smallholder dairy farming system.

Introduction

India’s dairy sector has seen a remarkable transformation over several decades, and it has become the largest milk producer in the world, accounting for about 21% of the world output (FAOSTAT, 2021) and growing at 6.2% CAGR with 210 million tonnes milk production in 2020-21.

However, it is characterized by a smallholder production system with small herd sizes and low productivity. NDDB decided to leverage and tap the existing potential of the small holder dairying system innovatively. A Manure Value Chain model was developed which focused on establishing “dung” as a commodity by attaching specific value to it. This enabled creation of demand in the small holder dairying system as the model provided avenues for additional income / savings to the farmers. At the same time, the model helped reduce methane emissions.

Experience of the National Dairy Development Board

In order to understand the social, economic and environmental impacts of the Manure Value Chain model, NDDB studied the results of the actual implementation of the model among 450 women beneficiaries in two villages of Mujhkuwa and Zakariyapura in Anand district of Gujarat.

To manage the operations in a structured manner and to develop a sense of ownership among the beneficiaries, NDDB helped establish India’s first women only manure cooperative. During the two years of its operation, the manure cooperative has made great strides in becoming economically viable. During the financial year 2021-22, the revenue of the cooperative was INR 65 Lakh which is an increase of about 350% from last year.

Based on the actual operations of the cooperative, an analysis was made on the incremental benefit being accrued to the farmer. It was found that in the year 2021-22, on an average 3000 Litre of slurry was procured and processed and the farmers earned Rs.1/Litre of slurry in these two villages. Here, it may be mentioned that the total slurry produced from a 2 cubic meter capacity biogas plant of the farmer is about 2000 Litre (varies upon feeding pattern). There are many biogas owned farmers who do not sell the slurry and use it entirely in their own field. The surplus slurry is procured from the willing farmers at least once a month.

The average monthly earning of a farmer in the year 2021-22 was about INR 1000/- from slurry sale. The remaining slurry valuing about INR 1000/- was utilised in their own field. Hence, the bio slurry has actually helped all the Flexi biogas owner farmers reap the benefit of INR 2000/- per month.

Further, the Flexi biogas owner farmers in these two villages saved equivalent to 1.5 Liquefied Petroleum Gas (LPG) cylinders per month on cooking fuel in the year 2021-22 which in monetary terms translates to INR 1500/- per dairy farmer family at current LPG cylinder prices. So effectively, a total of 450 Flexi biogas owned farmers in these two villages have accrued benefits amounting to INR 3500/- per month per farmer from the savings in usage of biogas and sale of surplus slurry.

The slurry procured from the farmers was processed and organic fertilisers were produced. The solid and liquid fertilisers thus produced were used as an alternative to chemical fertilisers or other type of highly priced fertilisers available in the market. These products are being sold in the market under the “SuDhan” brand which is a trademark of NDDB for promotion and sale of slurry based organic fertilisers across the country.

NDDB has also conducted a study with Anand Agriculture University- a reputed University in India, on the efficacy of the “SuDhan” products. Summary of the findings in table 1.

“This innovative approach to operate a dairy plant through renewable energy will begin a revolution in the field of green energy consumption in dairy sector enabling reduction in GHG emissions.

Meenesh Shah Tweet

Effects of the “SuDhan” Products

It also resulted in improvement in quality of grains in terms of protein, micronutrient content, enhanced microbial quantity in soil helping in soil health improvement and reduced up to 25% in use of chemical fertilizers.

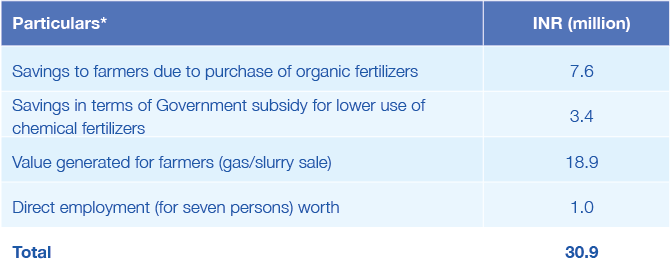

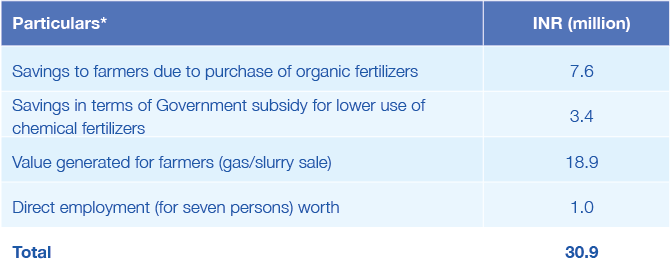

Based on the data generated during implementation of the model in these two villages, the total value generated for the 450 Flexi biogas plant beneficiaries in this project in terms of the savings due to usage of low-cost organic fertilisers, savings to Government in terms of subsidies for chemical fertilisers, employment generated etc. was assessed and a summary of the same is provided in table 2.

Therefore, the project was able to create value to the tune of INR 30.9 million working with 450 farmers.

Besides the wealth creation and establishment of the circular economy at the village level, the Manure Value Chain model has many positive social (women empowerment), economic (income & benefits) & environmental (reduction in methane emission) impacts. Some of the areas where NDDB has focused under this model are summarized below:

a) To promote scientific application of Bioslurry by the farmers, indigenously developed slurry applicators have been introduced for providing Bioslurry Application as Service (BaaS) to the farmers on shared basis. These applicators are designed for injection of slurry into the soil instead of using spraying method. This mode of application helps better absorption of carbon.

b) NDDB is in the process of securing carbon revenues for these projects so as to ensure sustenance of the projects on a long-term basis. Further, efforts are being made to create standard operating procedures/ mechanisms for measuring emission reduction due to application of organic fertilisers as substitute to chemical fertilisers.

Further, a nation-wide study conducted by Japan based Research Institute for Humanity and Nature showed that average per capita Carbon Footprint (CF) of Indians is 560 kg per year. If we extrapolate this value to a typical Indian household of 5 persons then the CF will be around 2800 Kg/year/family. If we consider the fact that with the installation of Flexi biogas plant an average household can reduce 5 tonnes of CO2 emissions per annum, then only the biogas component of the Manure Value Chain model has potential to reduce emissions in a substantial manner, leave alone the impact from replacement of chemical fertilisers. For a test case of 450 households the potential reduction in emission would be to the tune of about 2250 tonnes per annum.

In a country like India, where almost 75 million households are related to dairying, it has huge potential in terms of its social, economic and environmental impact.

Collaborative Approach for sustainable impact

In Indian Dairy Farming System, the smallholder farmers have very limited resources and in order to mitigate challenges with respect to climate change, the interventions so planned has to be both remunerative to the farmer and easy to adopt.

NDDB is working in this regard both at the policy level with Government of India and the dairy cooperative sector in general. The need to propagate the Manure Value Chain as a viable business enterprise is presently being spearheaded by NDDB through collaboration with Government & philanthropic organisations for scaling up and implementing the manure management initiative across dairy cooperative ecosystem in the country. Presently, the model is being replicated across 8 States in the country. Government of India has also recognised this model under its “Gobardhan” scheme and NDDB as a technical partner will support implementation of the manure management model across the country.

Further, based on the learnings from the small-scale biogas projects and to upscale the concept, NDDB has conceptualized a large scale unique model to meet the energy requirements of a diary processing plant through biogas.

NDDB is implementing one such Biogas Based Energy Generation project at Varanasi Milk Union in Uttar Pradesh which will help meet the electrical and thermal energy needs of the dairy plants. Varanasi dairy will be the first dairy plant in India to run on biogas-based power generated from dung procured from dairy farmers.

The solid & liquid fertilizers produced from this plant will be sold to dairy farmers at reasonable prices through the supply chain used for providing other inputs which will open new avenues for organic farming and help to reduce the chemical deposition in the agricultural fields.

This innovative approach to operate a dairy plant through renewable energy will begin a revolution in the field of green energy consumption in dairy sector enabling reduction in GHG emissions.

References

Rath, D & Patel K.P, Manure Value Chain – An efficient model for doubling Farmers’ Income, Indian Farmer 7(06): 493-501 (2020)

A report on Effect of Biogas Slurry based SuDhan Products on growth and yield of wheat (Rabi) and Maize (Kharif) crops conducted by Anand Agricultural University.

Study by Japan based Research Institute for Humanity and Nature, January 2021.

EAT-Lancet Commission: Brief for Farmers

FAO: Food Wastage Footprint & Climate Change