Share this page

Alignment with SDGs

AUTHOR

Harendra Pratap Singh, Vishal Trivedi, Lalita Oraon, Ketan Dave, Aditya Jain, D K Sharma Product and Process development, NDDB, Anand, Gujarat, India - 388001

Background

Ready-to-eat foods (RTE), also called convenience foods, are commercial preparations designed for ease of consumption and convenience. Urban lifestyles, increasing distances between home and the workplace, women at work, and changes in family cohesion are all factors increasing the demand for processed, RTE food. This has resulted in a very active food processing industry in the business of manufacturing RTE foods. According to some report published the global RTE food market is expected to grow at a 21.8% Compound Annual Growth Rate (CAGR) during the forecast period 2018-2023 (Mordor Intelligence, 2017).

Yet, the RTE foods currently available in the market are not considered to be healthy choices. Keeping view of people’s desire for a healthy, nutritious, palatable and independently consumable RTE food, NDDB took up the work of developing an RTE meal which can overcome the disadvantages of the currently available fast foods in the market.

The Process

During the product development phase, several concepts were tried upon, like dry premix for corn flakes, layered food containing dairy and non-dairy ingredients, cake-like cereal-dairy combination products etc. After working on many such concepts and giving due consideration to consumer preferences for taste and health, the concept of mixing and processing together the milk derived protein, cereals, pulses, vegetables and spices was finalized. A product was prepared which was based on the finalized concept. The product achieved a high sensory score during organization level sensory evaluation. The product processing was designed in a way that minimum loss is occurred to the nutrients present in the raw materials used in the product. Also, it is a known fact that protein from vegetable and animal sources (milk in this invention), has supplementary effect when consumed together as these provide different sets of essential amino acids.

Following objectives were taken into consideration while developing the present form of invention:

To prepare an RTE meal containing the essential macronutrients in a proportion close to that required by the human body that:

- capable of providing minimum 25 percent of human daily requirement of fat, protein and carbohydrates per serving.

- can be used as a delivery medium for micronutrients (vitamins and minerals) in humans.

- can be used as relief food material during calamities like flood, drought, war, famine, etc.

- can be consumed while travelling.

- can be used as nutritious alternative to junk foods available in the market yet retaining the deliciousness.

- can be stored for minimum 6 months.

- without addition of preservatives or synthetic ingredients.

- can be manufactured using existing processing technologies.

- in which protein is derived from multiple sources for availing benefit of enhanced bioavailability and digestibility of protein.

Materials and methods

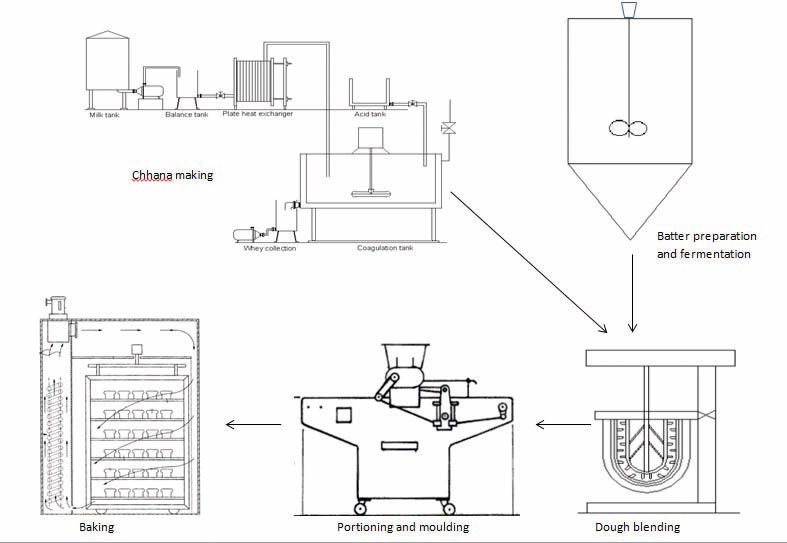

A process was standardised for commercial manufacturing of the product which involves following steps:

1. Preparation of cottage cheese (chhana/paneer)

It may be prepared either by using traditional Indian methodology or by any other process which may involve manual processing, mechanization/semi-mechanization, enzyme treatment, membrane processing technology and similar processes, either singly or in combinations. The traditional process involves following steps:

a. Standardization and pre-treatment of milk: Milk is standardized to preferably but not limited to 4.5% fat and 8.5% SNF. Milk derived cream and skimmed milk powder/whole milk powder might be used for the purpose of standardization. The standardized milk is then heated to 85°C to 95°C and held at this temperature for 10 min. However, any other suitable time-temperature combination might be used for the purpose of whey protein denaturation and to ensure microbiological safety of the product.

b. Coagulation: The heat-treated milk is brought to 70-90°C and coagulated at this temperature using freshly prepared 1-2% citric/lactic acid solution (actual citric /lactic acid requirement is approximately 0.2% of the milk) or any other permitted coagulant. The coagulant is slowly and continuously added to the milk till the milk gets coagulated and pH of whey reaches 5.0 – 5.5. The coagulated milk is then kept undisturbed for 5-10 minutes.

c. Draining of whey: When coagulation is complete the curd is allowed to settle down, the whey is drained out and the coagulum is wrapped into sanitized muslin cloth. The muslin cloth containing the coagulum is then hung onto a hook for 10-15 minutes for further draining whey, and then placed into the potable chilled water till further processing.

2. Preparation of cereal-pulse batte

Coarsely ground rice/wheat/corn flour, pigeon pea flour, chickpea flour and black gram flour are mixed in the ratio of 50:25:12.5:12.5 respectively or any other suitable combination. Moong dal flour and other lentils/cereals may also be added. Equal quantities of whey/water and flour are mixed together and kept for 4-6 hours for soaking. Alternatively, ingredients (rice/wheat/corn, split pigeon pea, chick pea, and black gram) may be soaked overnight in potable water and then ground to make a paste. Fermentation of the batter may be done for flavour enhancement and increasing the digestibility of the product. If fermented batter is made, then a suitable culture (bacteria or yeast based or mixed) may be added to the batter. The batter is then incubated at 30 to 40°C for 4-8 hours and then transferred to refrigeration (below 10°C) till further processing. Fermentation without external culture addition is also possible due to presence of indigenous micro-organisms in batter.

3. Preparation of dough

The soaked cereal-pulse batter and chhana/paneer are put together in a planetary mixer. Required quantities of grated bottle gourd or cucumber or carrot, green chilli paste, garlic paste, ginger paste, salt, sugar, turmeric, baking powder, citric/lactic acid are also added to the mixture in a suitable combination as preferred. Other spices/condiments/herbs/fruit pulp/fruit chunks/vegetables etc. may also be added at this stage. The mixture in blended in the planetary mixer till a smooth pasty texture is achieved.

4. Moulding

The prepared dough is distributed in suitable sized food grade non-stick coated moulds made of stainless steel or aluminium or silicone. If non-stick coated moulds are not available then baking paper or banana leaf lining may be done in the inner surface of the mould. Moulding may not be required for shapes like cookies or biscuits. Moulding process may either be manual or automated.

5. Baking and cooling

The moulded product is placed inside a time-temperature controlled bakery oven pre-maintained at 200-250°C. Alternatively, continuous baking tunnels may be used. The product is baked till desired level of browning is achieved on the outer surface of the product. This normally takes 20-40 minutes in an industrial oven. The baking imparts a typical aroma to the product. After baking, the product is allowed to cool to room temperature. For rapid cooling, dehumidified forced air circulation may be used.

6. Application of toppings

Topping may or may not be done. Topping ingredient may include vegetarian (as per the Indian food law) ingredients such as cheeses, capsicum, tomato, oregano, chilli flakes, paneer, etc. or non-vegetarian ingredients such as boneless chicken, mutton, pepperoni, etc. Toppings may consist of single ingredient or combination of ingredients. Toppings may vary based on preferences.

7. Packaging

a. For product with topping: The individual units of the product may be packed in any suitable food grade packaging material. Microwavable/oven safe containers may also be used for product packaging as this will eliminate the requirement of shifting the product to another vessel for thawing and consumption.

b. For product without topping (base only): Either individual units may be packed in a suitable packaging material or multiple units may be stacked together in a single pack, duly separated from each other with appropriate partitions between the units so as to prevent sticking of the units with each other during freezing process.

8. Storage

The product may be frozen to achieve longer shelf-life. For frozen storage, the product is generally stored below -18⁰C. Freezing tunnels may also be used. For shelf-life of 7-10 days, the product may be stored under refrigeration (8⁰C or below). At ambient temperature, the product may be stored for 2-3 days when properly packed in polythene or PP cup.

9. Thawing for consumption

The frozen product is required to be thawed before consumption. Thawing may be done in microwave oven or in steaming vessel. For thawing in microwave oven, the product container may be microwaved at “defrost” setting for 2-3 minutes, then kept as such for 2 minutes for even distribution of heat in the product and then again microwaved (microwave + convection mode) for 1-2 minutes. Alternatively, the frozen product may be transferred from the freezing chamber of the refrigerator to the cooling chamber for 24 hours for de-freezing and then heated for suitable time in microwave oven, OTG, steamer or tawa before consumption.

In India we have developed a ready-to-eat Dairy-based meal that provides nutrition while retaining the deliciousness

Harendra Pratap Singh Tweet

Key outcome

A healthy and nutritious product, the “RTE Dairy-based Meal” was obtained as an outcome. This product is a unique combination of cottage cheese (chhana/paneer), cereals, pulses, vegetables and spices which makes this product a standalone source of protein, carbohydrate, fat and dietary fiber together. The product can provide 25% or more of daily requirement of fat, protein and carbohydrates per serving along with the benefit of enhanced bioavailability and digestibility of protein. The product can be consumed as such or after heating it in a microwave oven or steamer. The product can be stored frozen, refrigerated or at room-temperature.

Nutrients are provided in a healthier proportion and can be adjusted as per nutritional requirement of the target population. Synthetic ingredient and preservatives are not part of the recipe. It is a vegetarian meal (as per the India food law) in which protein has been derived from milk and pulses. As a known fact, the protein derived from multiple sources is more nutritious in terms of amino acid profile and bioavailability. Toppings may be of vegetarian or no-vegetarian type depending upon consumer preference.

Relevance of the topic on the future of the dairy sector

The product is aimed at providing nutrition while retaining the deliciousness. The results of sensory evaluation have indicated high acceptance of the product among the general population.

The product may prove very useful for bachelors, working couples, frequent travellers, early morning office goers, etc. Apart from that, this meal also has potential to be used as relief food material during calamities like flood, drought, war, famine, etc. or may be used as comprehensive food package for security forces deputed at remote border locations where availability of fresh food is an issue and the temperatures allow prolonged storage of food without the need for refrigerators etc.

References

Mordor Intelligence (2017) Ready to Eat Food Market Size, Analysis – Growth, Trends, and Forecasts (2018- 2023) https://www.mordorintelligence.com/industry-reports/ready-to-eat-food-market. Last accessed 16 December 2018.