Share this page

The milk tree - technology and use

The dairy sector processes raw milk into an array of products and by-products, which have a range of uses.

The perishable nature of milk demanded early innovators to consider basic preservation techniques to extend its shelf-life. Fermentations based on lactic acid production led to a generation of soured milks and eventually cheese when it appeared that storing milk in ruminant pouches benefited from the associated enzymatic activity.

Innovation in preservation techniques

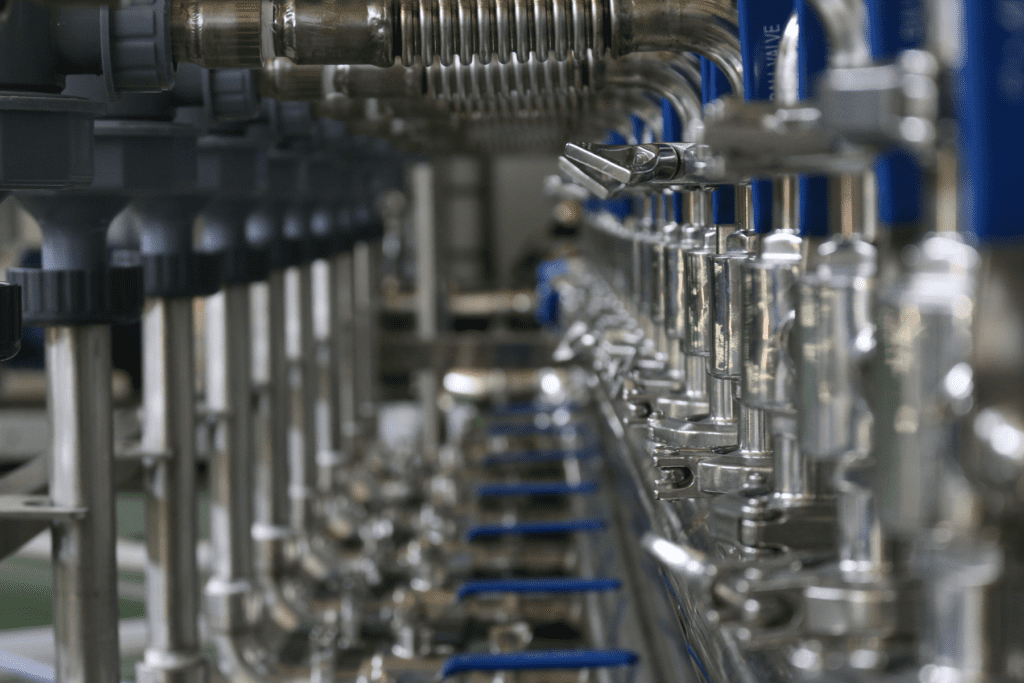

A range of innovative techniques have been implemented by the dairy sector to extend shelf-life and range of use:

- Gravity-based separation dominated early artisanal production of energy-rich butter until the centrifugal cream separator was developed in the early 1870s.

- Homogenisation was introduced in conjunction with pasteurisation in order to eliminate cream plugging in retailed bottles of liquid milks.

- Concentrated milk products such as evaporated milks and sweetened condensed milks were preserved by heat sterilisation and sugar addition.

- Dehydration following pre-concentration provided the ultimate level of preservation initially for milk and skim milk and later for a whole generation of ingredients derived from milk.

- Fermented milk-based beverages have historically enjoyed global appeal while maintaining diverse cultural identities internationally.

Examining the science of dairy products:

- Milk coagulation/precipitation is a central step in the production of a large range of cheese and casein-based products.

- Pioneering work on the recovery of protein from whey using membranes is now applied widely to milk separations.

- Combining milk with sugar and cocoa is key to the production of confectionary products such as toffee, fudge, and chocolate.

More detail about each of these processes is available in the table below:

Gravity-based separation dominated early artisanal production of energy-rich butter until the centrifugal cream separator was developed in the early 1870s. This set in motion the first steps of industrialising dairy processing according as sources of motive power were invented. Milk pasteurisation using the high-temperature, short time holding (HTST) method became widely adopted in response to public health legislation.

Gradually, homogenisation was introduced in conjunction with pasteurisation in order to eliminate cream plugging in retailed bottles of liquid milks.

Concentrated milk products such as evaporated milks and sweetened condensed milks were preserved by heat sterilisation and sugar addition (to control water activity), respectively. The reduced milk volumes of these concentrated milks was logistically important during preparation of troop rations during the Great Wars.

Dehydration following pre-concentration using roller- and spray-drying methods provided the ultimate level of preservation initially for milk and skim milk and later for a whole generation of ingredients derived from milk.

Fermented milk-based beverages have enjoyed global appeal for many years while maintaining diverse cultural identities internationally. An increasing appreciation of the tentative relationship between fermenting microorganisms and gut microflora is reflected in the increasing range of fermented milks aimed at promoting a healthier microbiome.

Milk coagulation/precipitation is a central step in the production of a large range of cheese and casein-based products. The curd formed as a result of clotting milk by enzymatic cleavage of the phe-met bond in k-casein is texturised during further processing to generate a multitude of cheese varieties in conjunction with the flavour contribution of fermenting microorganisms.

Alternatively, after such curd is formed from skim milk, successive washing steps leads to the production of dried rennet casein. When acid is used to coagulate milk at its isoelectric pH, the washed and dried curd that results is known as acid casein. Acid casein may be further processed by solubilisation using alkali e.g. NaOH to produce sodium caseinate in spray dried form. Subtle compositional differences in the individual whey streams from these precipitation processes makes facilitate alignment with a choices of next stage process treatments/ingredient applications e.g. acid casein whey as a substrate for the production of high-gelling whey protein concentrates.

Pioneering work on the recovery of protein from whey using membranes is now applied widely to milk separations.

Industrial chromatography takes protein fractionation to a more detailed level. The functionality of these proteins/protein fractions may be further mediated by pre- and post-processing treatments such as heat treatment and/or combination with other ingredients e.g. specific ions and proteins. Enzymatic hydrolysis of proteins using selected enzymes may be used to improve functionality, reduce allergenicity and release targeted peptides. Retention of bioactivity in selected protein fractions and peptides demands the use of milder processing treatments such as ultra-high pressure processing.

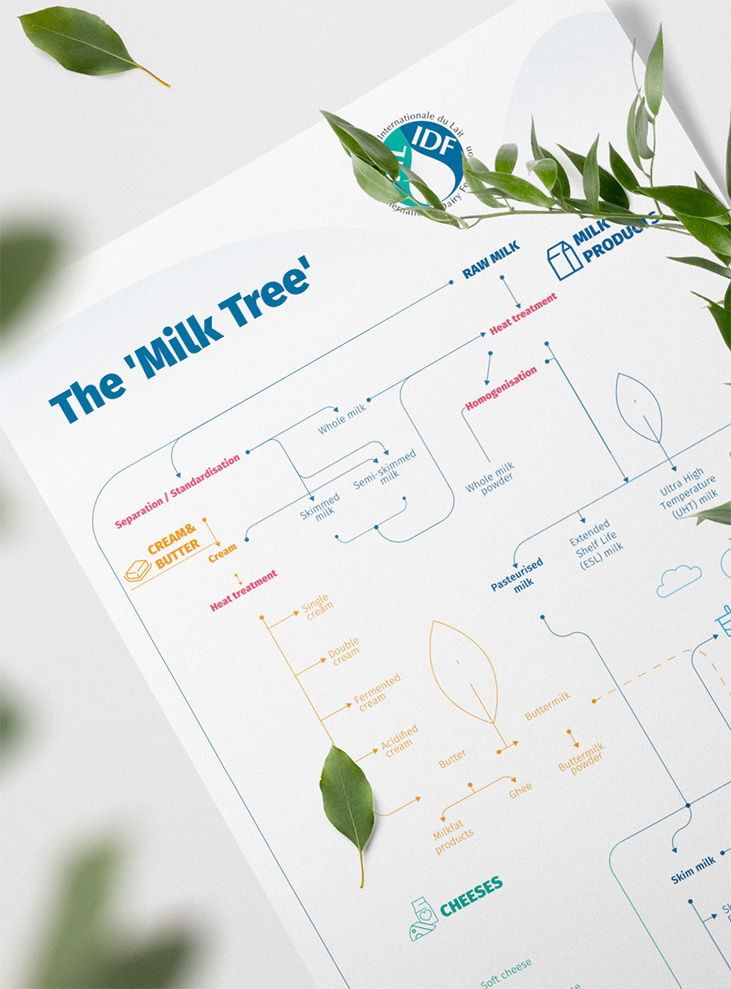

The 'Milk Tree'

The dairy and wider food sector processes raw milk into a vast array of products including cheese, butter, yoghurt, cream, condensed milk, and dehydrated milk. The dairy sector also produces various byproducts including buttermilk, whey, ghee, and skim milk. These dairy byproducts have high nutritional value and have applications in many food industries as well as non-food applications.

Learn more about the many different ways that milk and milk products are developed and used with the IDF’s useful Milk Tree infographic, including details on:

- Whey products and their various uses

- Cheese varieties and products

- Fermented milk products

- Milk products and processing stages

- Cream and butter

Learn more about dairy science & technology

The breadth of issues IDF covers in its work is extensive. Find out more about the work we do.

Fermented dairy products

Fermentation is a natural way to keep foods fresh and safe throughout shelf life.

Read MoreTechnology behind cheese making

To make cheese, milk is fermented and concentrated by removal of water through the coagulation of th...

Read MoreDehydration of dairy products

Dehydration is an important operation used by many dairy processors to extend the shelf life of milk...

Read MoreDairy focused Membrane Processing

Physically separating and selectively concentrating milk components.

Read MoreRelated reports & publications

IDF provides a permanent source of authoritative scientific and other information on a whole range of topics relevant to the dairy sector.

Related news & insights

IDF provides a permanent source of authoritative scientific and other information on a whole range of topics relevant to the dairy sector.